This is why we hammock factory loves SWAYY hammock

Manufacturing in China: How the Chinese SWAYY’d Me.

As I begin I would like to make an introduction that is more or less a disclaimer: I am an American and I take pride in the fact that I live in a country that lifts freedom and liberty above dictatorship and popular opinion, even if at times the fabric of our great country is deteriorating. That said, please read on and know that these are opinions formed from my own experiences on hammock factory.

Just a few weeks ago, I was boarding my first of three planes headed toward Ningbo, China. Time had forced my hand to make a key decision before I had even left: To manufacture in China.

When I started SWAYY in 2014, I had a romantic view of manufacturing, especially of the textile industry. I had great plans to employee Americans, pay them well, and bring the dying skill of technical sewing back to the U.S., especially in the south. After my first contact with a medium-sized sewing establishment of about forty sewers, I was turned down, not too big of a deal as I figured that this would be a trend — be denied several times and then strike a business deal. However, after seven manufacturers and years of wasted time, I learned a great deal.

One lesson I learned is that Millennials (yes, I am a Millennial and proud of it) are not the first generation to suffer from “entitlement syndrome”, sorry to burst that bubble. There is a great saying that goes something like this: the industries right for disruption are those that are fat and happy. If American business can be compared to an industry, guess what? It’s fat and happy. With this disease comes entitlement.

Over the course of three and a half years, I worked my way down the eastern sea-board of manufactures. I was constantly met with the same scenario: I would approach a sewing establishment. They would be interested http://www.layersedge.com/. I would show them the prototypes; they would ask for more information. I would give them a sample and materials; they would be interested. I would wait… and wait… Waiting… Waiting… Nothing.

Once they found out that I wasn’t going to be pushing 20,000+ units in the first 6 months, the silence began. If I phoned, I quickly realized that no one had the courage to tell me they weren’t interested; instead, they strung me along. Sadly, it took me, 7 different manufacturers, to learn my lesson. On the 7th try I had sent 2 production-ready prototypes, $400 in materials, drawings, and a dash of personal encouragement to a “quality first, made it USA ra ra ra!” facility. After 4 months I was finally on my way to pick up the 2 new promised prototypes. I arrived to find some of my material damaged and a 3%, a half-baked prototype that was grossly unfinished. To say the least, I was very upset inside, but I gave them another chance. Well, it was my mistake and once again I was left with nothing.

By this time, we were over 60% the way through our Kickstarter and I had no manufacturer in place. All of my eggs had been placed in one basket, and the basket was set on fire and punted into a black hole. So I had a decision to make — do I try to hire a few people to help me make the products, or do I go to China and visit a few factories that have been inviting me over to give them try? Well, as you already know, I decided to go to China.

In general, expectations can be quite dangerous. When I have had expectations in the past, I have often been left feeling incredibly let down. However, I tend to still have them and I am not totally sure that I will ever be able to live a life without them. While on my way to China I had expectations, fairly intense ones as I expected to have at least one sample produced from each factory I visited before returning home. Long story short, the good friends I was blessed to meet completely and utterly blew my expectations out of the water! In fact, I was able to have 3 prototypes made in a matter of 2 days from one factory, and 2 from another in a day and a half. WOW! And to think it took nearly 4 months in the U.S. to get a half-baked prototype . . . this absolutely blew me away.

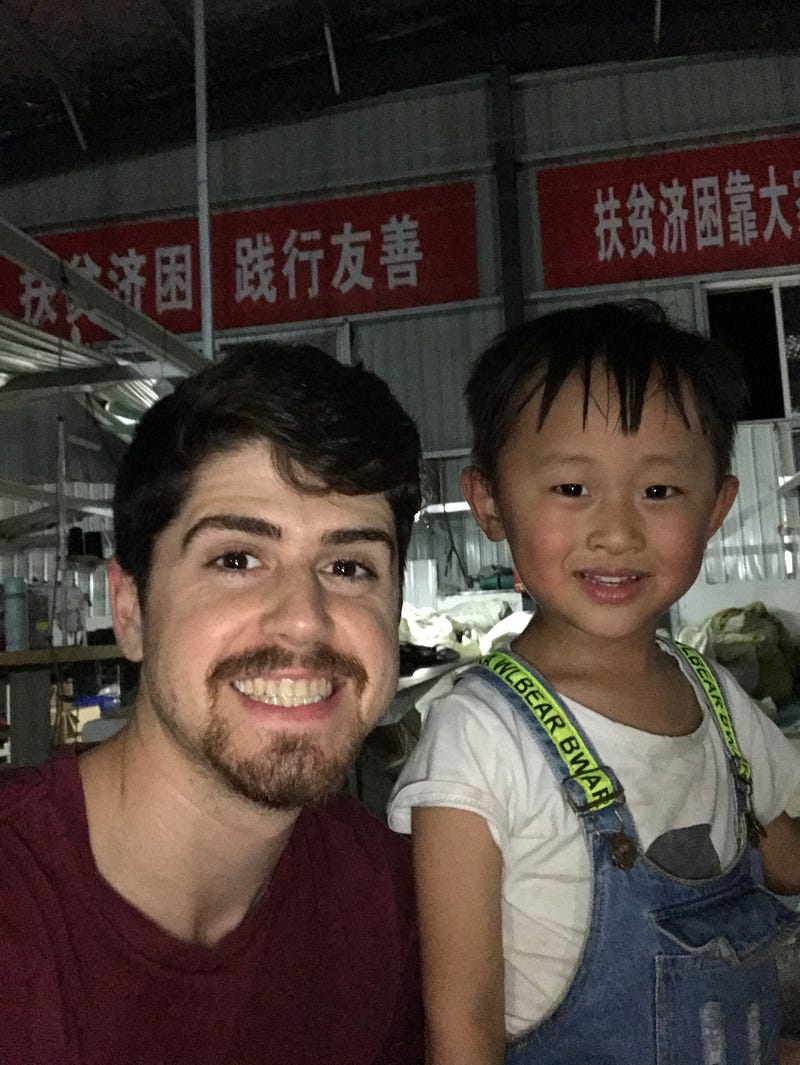

Side Note #1: Here is a picture of Ace and his cousin from Hefei, hammock factory. Super awesome guys! If you look close in the background you might see another American hammock company! They are a good hammock factory.

What really stood out to me was the rapid pace that the Chinese were able to combine my verbal ideas with the physical product samples in such haste. It’s not that the Chinese quality is all that better to be honest, although the skill pool is much larger there, but the level of execution that was able to be accomplished added tremendous value.

Side Note #2: Here is a cool video I took inside a potential supplier factory for the Special webbing we use for our hammock suspension systems:

Here’s another thing; while I was in the country I didn’t have to pay a single dollar for anything. My room, food, transportation, everything, was all taken care of. I wasn’t even allowed to lift my suitcase into the cars that picked me up — I was treated like royalty. And after reflecting on the trip I walked away amazed at how incredible the art of building relationships in China is. They know how to serve and to serve well!

Ever since I was a young boy I have loved the idea, concept, and materialization of factories and assembly lines. The TV show How It’s Made was a key inspiration in shaping how I think today, and I still get butterflies when I walk through various factory floors — yes, I am serious!

In my opinion, we beat the drum of American capitalism while our march is out of cadence. I believe it’s time to get back to being a humble nation, speaking kindly, and making a difference with our actions. Are the working conditions in China less than that of the U.S.? Yes, most factories don’t have AC. But here’s a news flash: AC isn’t needed to make great things happen. Ask the Egyptians, the Romans, or the Israelites! Sure, climate control makes life more enjoyable, but seriously, we have grown so self-consumed about what makes us comfortable that we have soured our ability to work with our hands and get dirty! The factories I visited had full-time cleaners who circled the entire factory to keep things tidy. Is it perfect? Not at all, but the grit and work ethic that flowed from the places I visited was overwhelmingly exciting. Want to make a difference? Work hard.

As I step off of my soapbox, I would like to say that I do love America, but I believe in an America that isn’t afraid to work and, more importantly, serve! God has blessed America, so let’s not squander our blessings.

Side Note #3: This is Ace’s cousin’s son. This little guy followed me around the factory some, and he stole my heart. What a fun kid!

Anyways, these are my thoughts and reflections about China. Lots of other fantastic things happened and I learned a lot. This trip humbled me, and I am motivated to help and serve others better now. Yes, the Chinese want my business and they see potential in our company, but let’s not forget, our first orders will only be for around 100–200 units. Considering the fact that they usually operate with companies working with thousands of units of a month, ours is a small contract. I guess they see something in SWAYY — I am still trying to figure out what that is. I do know one thing though: China is a wonderful place with a lot of loving people, so let’s not easily throw the “Made in China = Cheap” stereotype any longer because I can attest, a lot of great skill can be found there. They have enabled our consumer-based economy to grow so much and so quickly. Keep pushing, keep serving, keep humble.

Encounter More,

Seth Hill

Founder of SWAYY

![3233232-608x400[1]](https://www.huilangfactory.com/wp-content/uploads/2022/05/3233232-608x4001-1.jpg)

![876787-496x400[1]](https://www.huilangfactory.com/wp-content/uploads/2022/05/876787-496x4001-1.jpg)